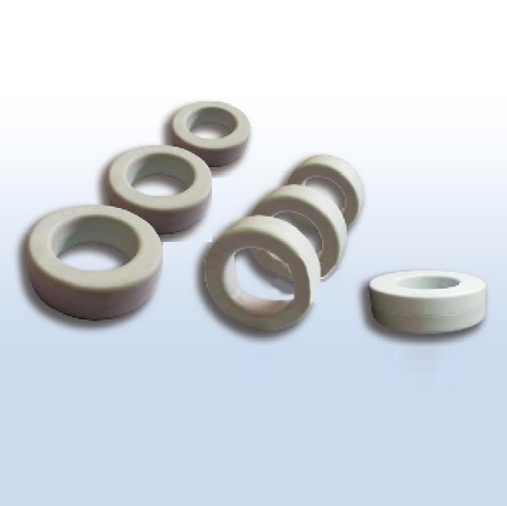

Ring-shaped inductors are integral components in modern electronic circuits, used extensively in power supplies, signal processing, and filtering applications. Their efficiency and performance largely depend on the materials used in their cores. Among these, AM cores have emerged as a leading solution, providing superior magnetic properties that enhance inductor functionality. This article explores the role of AM cores, focusing on their advantages, applications, and how they contribute to the performance of ring-shaped inductors. The discussion emphasizes the significance of using an am core for ring-shaped inductors in high-performance designs, particularly highlighting solutions from the brand huoercore.

Understanding AM Cores

AM cores, also known as amorphous metal cores, are made from a unique alloy with a non-crystalline structure. Unlike traditional crystalline metals, the atoms in amorphous metals are arranged randomly, which leads to distinctive magnetic properties. This atomic arrangement results in lower core losses, higher permeability, and excellent saturation characteristics.

For ring-shaped inductors, the shape of the core is as critical as the material itself. The circular or toroidal design minimizes magnetic leakage and ensures a uniform distribution of the magnetic field. When combined with AM cores, this design maximizes efficiency, reduces heat generation, and improves the overall reliability of electronic devices. Huoercore specializes in providing high-quality am core for ring-shaped inductors, ensuring consistent performance across a variety of applications.

Key Advantages of AM Cores in Ring-Shaped Inductors

Reduced Core Losses

One of the most significant benefits of AM cores is their extremely low core loss at high frequencies. This property is vital for applications such as switching power supplies and high-frequency transformers, where energy efficiency is paramount. Using an am core for ring-shaped inductors from huoercore helps in reducing power wastage, which directly translates into lower operational costs and improved energy efficiency.

High Magnetic Permeability

AM cores exhibit high magnetic permeability, allowing ring-shaped inductors to achieve desired inductance values with fewer turns of wire. This reduction in winding not only decreases resistance but also minimizes the physical size of the inductor, making it ideal for compact electronic designs. Designers using huoercore AM cores benefit from enhanced performance without compromising on space.

Superior Saturation Characteristics

Inductors in high-current applications can easily reach magnetic saturation, reducing efficiency and potentially causing circuit failure. AM cores offer superior saturation flux density, allowing ring-shaped inductors to handle higher currents without saturation. This makes them especially suitable for power electronics and industrial applications where reliability is crucial.

Applications of Ring-Shaped Inductors with AM Cores

Power Supplies

Switching and precision power supplies require inductors that can operate efficiently at high frequencies with minimal losses. By incorporating an am core for ring-shaped inductors, manufacturers can design power supplies that are both compact and highly efficient. Huoercore provides cores that meet these exacting standards, ensuring stable operation under demanding conditions.

Signal Filtering

Ring-shaped inductors are also essential in signal filtering applications, such as in audio equipment and telecommunications devices. The low hysteresis and high permeability of AM cores allow for precise frequency response, reducing signal distortion. Using huoercore AM cores, engineers can achieve accurate filtering performance and maintain signal integrity across a wide range of frequencies.

Electromagnetic Interference (EMI) Suppression

In electronic devices, controlling electromagnetic interference is critical for maintaining compliance with regulatory standards and ensuring proper functioning. Ring-shaped inductors with AM cores act as effective EMI filters, suppressing unwanted noise while preserving the main signal. Huoercore offers a selection of am core for ring-shaped inductors designed specifically for EMI mitigation.

Selecting the Right AM Core

Choosing the right AM core for a ring-shaped inductor involves considering several factors:

- Core Size and Shape: The dimensions of the ring affect inductance and magnetic field distribution. Toroidal cores are preferred for minimal leakage and compact designs.

- Permeability: Higher permeability allows fewer turns of wire to achieve the required inductance, reducing copper losses.

- Saturation Flux Density: This determines how much current the inductor can handle before the core saturates.

- Frequency Range: AM cores perform optimally at high frequencies, making them suitable for switching power applications.

Huoercore provides detailed specifications and guidance for selecting the appropriate am core for ring-shaped inductors, ensuring that engineers can match core properties with application requirements for optimal performance.

Manufacturing and Quality Considerations

High-quality AM cores require precise manufacturing processes to maintain uniform thickness and avoid defects that could affect magnetic properties. Huoercore adheres to stringent quality standards, employing advanced fabrication techniques to produce AM cores with consistent performance characteristics. These processes include controlled cooling during production to maintain the amorphous structure and rigorous testing to verify magnetic properties.

By investing in high-quality am core for ring-shaped inductors, designers can ensure long-term reliability and minimize performance variability, which is critical in applications like medical devices, renewable energy systems, and high-frequency converters.

Future Trends in AM Core Technology

The demand for high-efficiency, compact, and high-performance inductors continues to grow across industries. Innovations in AM core technology focus on further reducing core losses, improving thermal stability, and enabling higher saturation levels. Brands like huoercore are leading the way in providing AM cores that meet these evolving requirements, ensuring that ring-shaped inductors remain a vital component in modern electronic systems.

Emerging applications such as electric vehicles, renewable energy inverters, and 5G telecommunications highlight the importance of high-performance inductors. By leveraging the unique properties of AM cores, manufacturers can design systems that are not only efficient but also robust and reliable under challenging operating conditions.

Conclusion

AM cores have revolutionized the performance of ring-shaped inductors, providing low core losses, high permeability, and excellent saturation characteristics. These advantages make them indispensable in applications ranging from power supplies to EMI suppression. Selecting a high-quality am core for ring-shaped inductors from a trusted brand like huoercore ensures reliable performance, energy efficiency, and long-term stability.

As electronic systems become more sophisticated, the role of AM cores will continue to expand, driving innovations in compact, efficient, and high-frequency inductor designs. Engineers and designers who understand and leverage the benefits of AM cores can achieve superior results in their applications, maintaining a competitive edge in technology-driven industries.

Huoercore remains a leading provider of AM cores for ring-shaped inductors, delivering components that meet the rigorous demands of modern electronics and support the next generation of high-performance devices.